Glanville Trenchless

At Glanville Trenchless, we believe trenchless solutions are more than just a service, they represent innovation and excellence in drainage and sewer rehabilitation and repair.

Leveraging our extensive experience and deep expertise, we effectively manage a wide range of trenchless (also known as 'no dig') projects, from small-scale repairs to large infrastructure developments, serving all types of clients throughout the South West region including domestic and commercial. Our commitment to sustainable practices ensures that we maintain the integrity of wastewater networks, even in challenging and remote locations.

"No-dig" techniques involve repairing drains, pipes, and sewers without the traditional approach of digging up and replacing the entire structure. Instead, a new pipe is installed within the existing one, avoiding extensive excavation.

This approach is versatile and can be applied to various situations, from residential repairs to large-scale pipes and culverts. Thus, it provides a more cost-effective solution by reducing disruption and downtime, shortening the time spent on-site, and eliminating the need for expensive surface restoration, such as repaving tarmac or replacing paving slabs.

Opting for trenchless or "no dig" solutions in drainage and sewer repairs provides a safer, more efficient alternative to traditional open excavation methods. These techniques are particularly beneficial in the South West, where terrain can be remote and difficult to access. Trenchless technology minimises surface disruption, significantly reducing the impact on traffic, businesses, and daily activities. This method not only preserves the existing infrastructure but also enhances project efficiency, making it ideal for areas where access and environmental sensitivity are paramount.

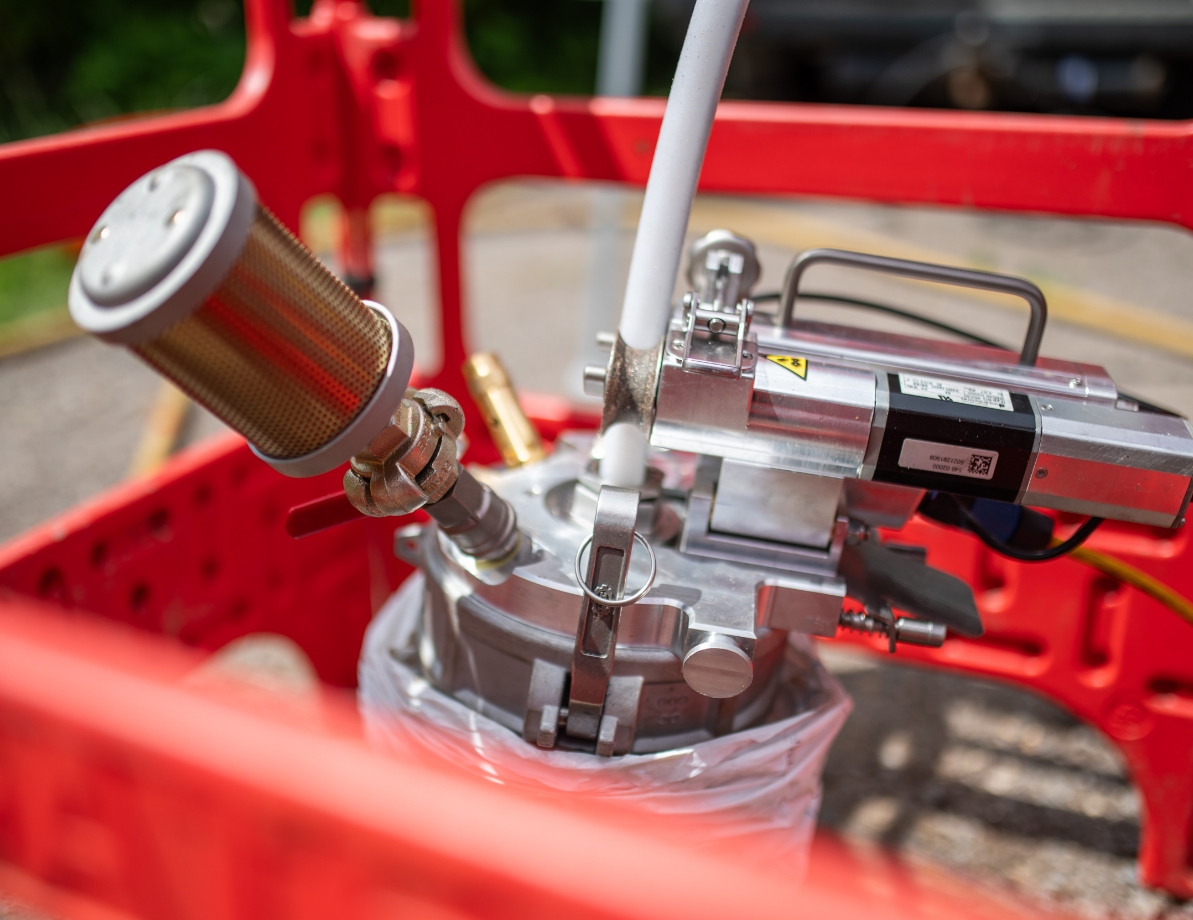

We have cultivated strong relationships with leading no-dig technology providers worldwide to ensure we utilise the best equipment available for trenchless solutions. Our trusted suppliers, including Bluelight Lining and RSM Lining Supplies, collaborate closely with us to deliver cutting-edge UV light curing technology. This advanced equipment significantly reduces curing times compared to traditional methods, allowing us to offer faster, more efficient services to our clients. By partnering with these industry leaders, we stay at the forefront of innovation in the trenchless technology sector, providing top-quality solutions that meet the diverse needs of our projects.

Using UV technology for pipelining and patching offers significant advantages. In this method, an LED light head is passed through a resin-impregnated material that has been inverted into the damaged section of the pipe. The LED lights then cure the resin, effectively creating a new pipe within the existing one.

One of the major benefits is the substantial reduction in CO2 emissions, achieving savings of between 90% and 99% compared to traditional heat curing systems. Additionally, the newly lined pipes have a minimum life expectancy of 50 years, ensuring a long-lasting and durable solution.

Our Expertise and Approach

Our team of skilled professionals excels in assessing each project to determine the most suitable approach, always aiming to minimise disruption and uphold safety standards. We conduct thorough pre-work surveys to choose the best solutions, prioritising trenchless methods wherever possible. This focus on less invasive techniques ensures sustainability and keeps environmental and societal disruption to a minimum.

Through partnerships with industry experts and continuous investment in top-of-the-line equipment, we offer cutting-edge trenchless technology solutions. Our commitment to rigorous training ensures our teams are equipped with the latest skills and knowledge, delivering optimal results for our clients.

Our main services include:

Our advanced trenchless solutions offer a faster, cleaner, and more sustainable alternative to traditional excavation. From complex pressurised mains to deteriorating pitch fibre pipes, we provide a full suite of no-dig rehabilitation technologies tailored to every challenge, minimising disruption while maximising durability and performance.

Trenchless Rehabilitation Services Include:

CIPP Lining (Cured-in-Place Pipe)

- Hot Cure Lining

- LED UV Lining

- Glass Reinforced Plastic (GRP) Lining

Pressure Main Rehabilitation

- SaniTube for Pressurised Mains

- Fero Force Lining for Large Diameter & High-Pressure Systems

Patch Repairs & Structural Upgrades

- Localised Patch Lining

- Pitch Fibre Pipe Repairs

- Top Hat Lateral Connection Seals

Civils & Structural Integration

- Civil Engineering Services, Including Sika Application

Specialist Tools & Techniques

- Manhole Rehabilitation Centrifugal System

- Robotic Cutting Services

- VIP Weco Internal Seals

Cured-In-Place Pipe (CIPP) Lining

CIPP is a versatile solution involving a resin-saturated felt tube that is inverted or pulled into the damaged pipe. The tube cures in place, forming a tight-fitting, corrosion-resistant, and durable new pipe. This method can be customised with different grades, thicknesses, and resin types to address various structural issues, offering both full-length and patch liners.

- Durability

- Minimal Disruption

- Quick Installation

- Improved Flow

- Cost-Effective

- Environmentally Friendly

- Improved Structural Integrity

- Reduced Infiltration/Exfiltration

- Root Intrusion Prevention

- Reduced Maintenance Costs

Lateral Repair System

Glanville Trenchless are the first UK company to invest in the New Prokasro Robotic Lateral Connection Rehabilitation System

- Rapid Trenchless installation of connection collars

- 200-600mm pipe diameters enabling connections from 150 mm to 225 mm to remotely seal connections.

- Effective sealing of the parent main prevents access and egress of liquids and gases

- Can be installed up to 80m from the access point

- CP655 Approved materials

- Optimum curing using an electrically heated base plate and balloon

Glanville Trenchless also offer smaller diameter Lateral repairs with their Picote Connection Collar system.

- 100 mm- 150mm Pipes and connections

- Both “T” and “Y” connection collars are available

- Can be installed up to 30m from the point of access.

- CP655 Approved Connection Collars

Patch Lining

Inflatable packers are used to allow flows to continue to pass through the system whilst the patch liner has been inserted in the defective areas, allowing the continued use of the system. This reduces the impact on customers, allowing continued use of their internal facilities. Our patching system can repair diameters ranging from 50mm – 1.2 metres in length. The general length of patch repair installed is on average 1 metre section at a time. All patch liners are installed to water industry standards.

Added Benefits:

- Reduced Carbon Footprint

- Preservation of Natural Habitat

- Increased Pipe Lifespan

- Improved Flow Efficiency

- Resistance to Root Ingress/Infiltration

- Versatility

- Precision Targeting

- Minimal disruption to traffic and pedestrians

- Lower repair costs

Manhole Chamber Sealing

Wet spraying requires a grout pump, grout and air hoses, a spray head, a compressor, and a mixing system that is suitable for making sprayable grout.

The mortar is mixed on site using a power mixer to combine the appropriate amounts of water and additives. This is mixed into a smooth grout of plastic consistency, as specified in the technical manual.

The grout is mixed and gravity-fed into a pump. The pump is linked to a high-pressure grouting hose with a spray head.

Depending on the infiltration and the final coating thickness required, the procedure described above is repeated in several passes. The maximum spray thickness of fresh grout never exceeds 5 to 10mm per coat.

Added Benefits of the Manhole Sealing:

- Infiltration

- Exfiltration

- Reduction of Odours

- Enhanced Structural Integrity

- Prevention of Corrosion

- Reduction of Maintenance Costs

- Compliance with Environmental Regulations

- Improved Safety

- Prevention of Soil Erosion

- Prevention of Insect and Rodent Entry

- Mitigation of Flooding Risks